Hot stamping plastic is an art in itself that transforms dull and simple items into trendy fashionable products with distinctive designs. Some people at Shunho Creative are specialists in this technique, and we aim to make everyone see how amazing and unique plastic products can be.

Hot stamping plastic is a method of making aesthetic prints on the plastic through the effect of heat and special foils. These foils are sometimes shiny or colorful and give the coils a nice finish. It uses a machine that heats up a metal plate with a design on it. This plate — known as a die — presses into the foil and then the foil adheres to the plastic. This gives shape or words that you slowly want to see on the face of the plastic. Here we have created a mind-blowing design that can make the blender catch the attention of anyone!

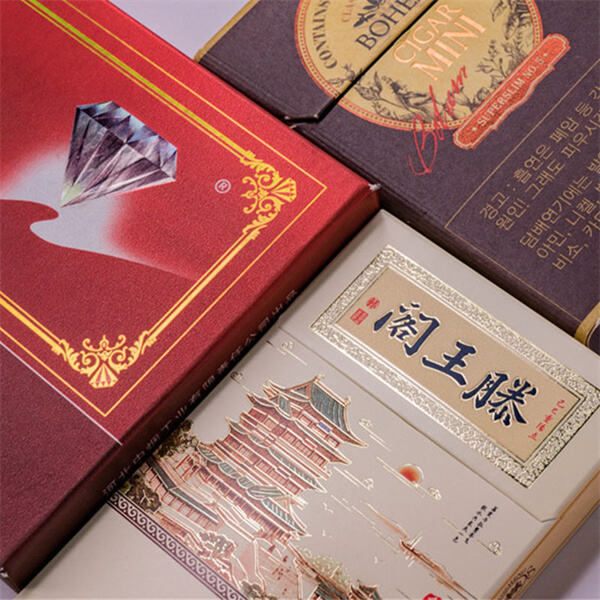

Hot stamping is usually used for beautiful products such as cosmetics, jewelry, watches and cocoa boxes. This technique makes plastic resemble metal or leather, giving it a sense of richness and value. There are many different types of foils for hot stamping, including shiny, dull, sparkly or rainbow. These different types of foils are used to make the plastic pop and show how different and unique it is against similar plastic products on the market. Therefore, you need to cater to a design that is audible to gain attention!

When it comes to hot stamping, it's not only instrumental in aesthetics but can also help brands display their names or messages on plastic products. This allows people to remember/familiar with the brand and can recognize in the store. When through hot stamping, it gives more exceptionality and professionalism to the product, and it also allows it to be differentiating against other similar products. It should be important for companies because that can attract customers and make them decide to buy their product over others.

Hot stamping can also be used to apply essential information such as safety warnings, icons, or instructions that help users understand the product. Hot stamping produces clear but permanent markings, which should remain visible even on the product after usage. This is incredibly useful because it prevents injuries and makes certain that everyone knows how to properly use the product. Moreover, hot stamping can accentuate characteristics and controls of a product, providing a simpler and more instinctive experience for all.

Hot stamping on plastic is incredible to see. It makes plastic seem ornate and formal. By creating differences in texture, color, and finish, hot stamping makes the product extremely eye-catching. Rainbow, shiny or colorful foils can give the look a burst of excitement or an effect that is resolutely softer, more subtle — dependent on outside influences, really. This design versatility allows businesses to please not just in functionality but also in aesthetics, which include other reasons for the application. Hot stamping is an excellent method to manufacture unique products that people will remember and wish to buy.

Languages supported include English, Spanish and Japanese.hot stamping plastic solutions from materials to final products.

The majority of customers come from the hot stamping plastic 500 companies in the world

With FSC, REACH, FDA 21 CFR 176.170, (EU) No 10/2011, TUV OK COMPOST HOME, RECYCLABLE, hot stamping plastic, CNAS, PATENTS and other environmental protection certificates

Laser hot stamping plastic production can reach an annual 200, 000 tonnes.